Carbide Burr Set – A Complete Solution

A carbide burr set provides you with multiple shapes and sizes, giving you flexibility in your grinding process. From narrow contours to larger surface areas, a well-curated kit ensures you have the right tool for the job, with each item in the set designed for specific grinding needs and made to high quality standards.

Die Grinder – Not Just for Coffee

While in coffee we think of burrs for grinding beans, the term also applies in die grinder tools for shaping metal, steel, aluminum, plastics, and other metals. Carbide burrs are engineered to efficiently cut through these materials, ensuring clean and precise results. This crossover of terminology reflects the material engineering behind high-precision grinding parts.

Frequently Bought with Quality Coffee Gear

Burr upgrades are frequently bought alongside premium grinders because they’re a direct upgrade to performance. For those looking for a good deal, pairing a grinder with a premium burr set can save money in the long term.

Some retailers also offer free shipping or include free accessories when you purchase premium burr sets, adding extra value for buyers.

Why Burr Quality Matters

Performance in grinding coffee is directly tied to the burr’s material, shape, and precision. A quality burr produces uniform grinds, avoids overheating, and ensures better flavor in your cup.

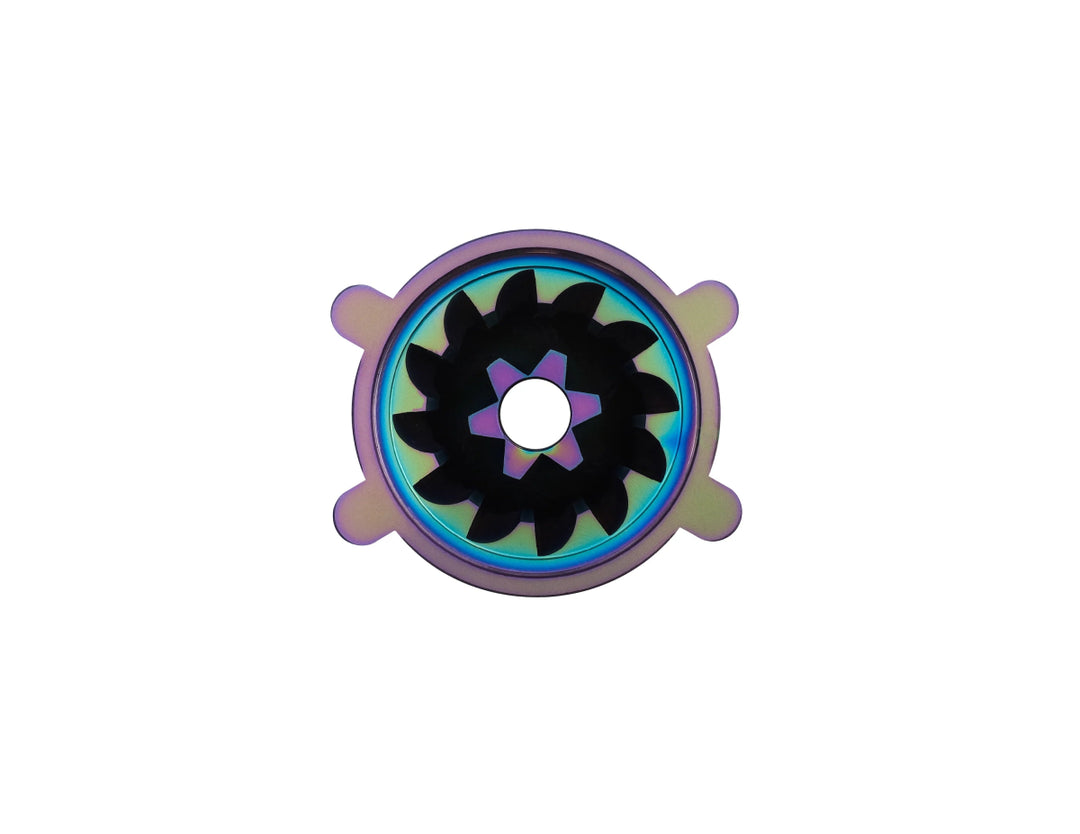

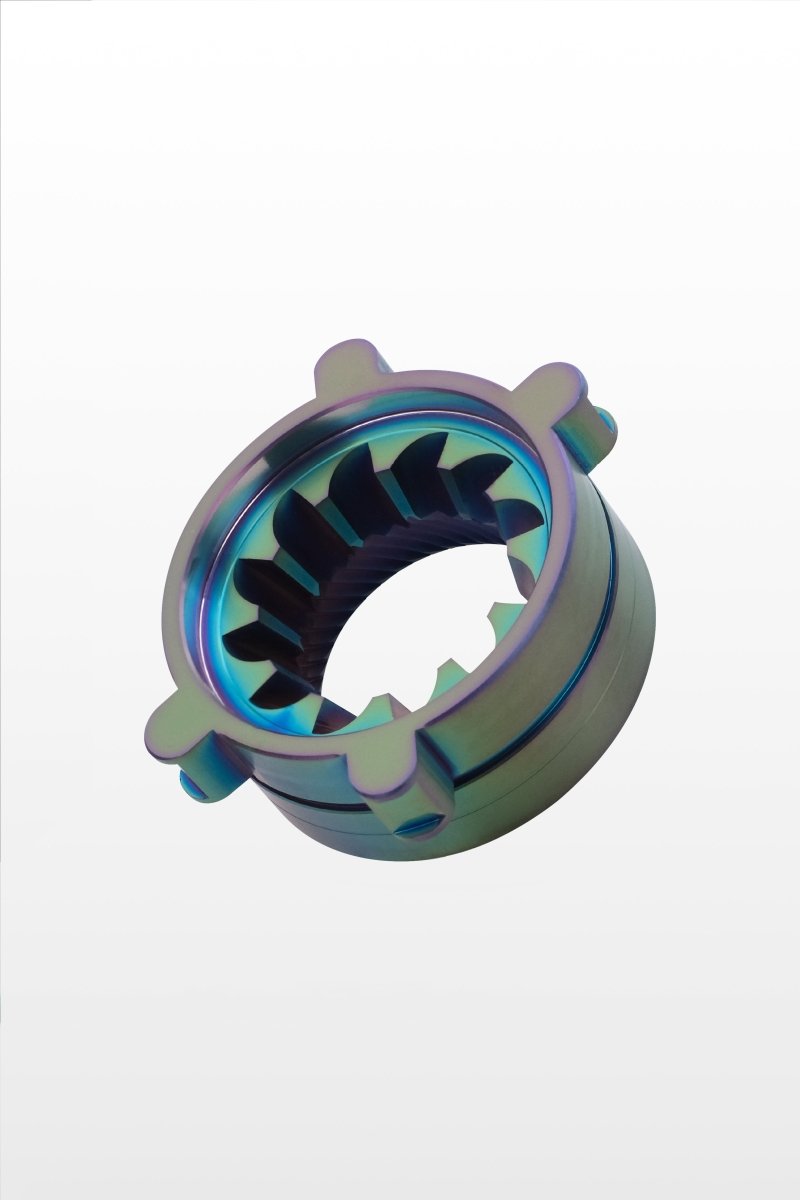

Material Choices – Steel, Aluminum, and More

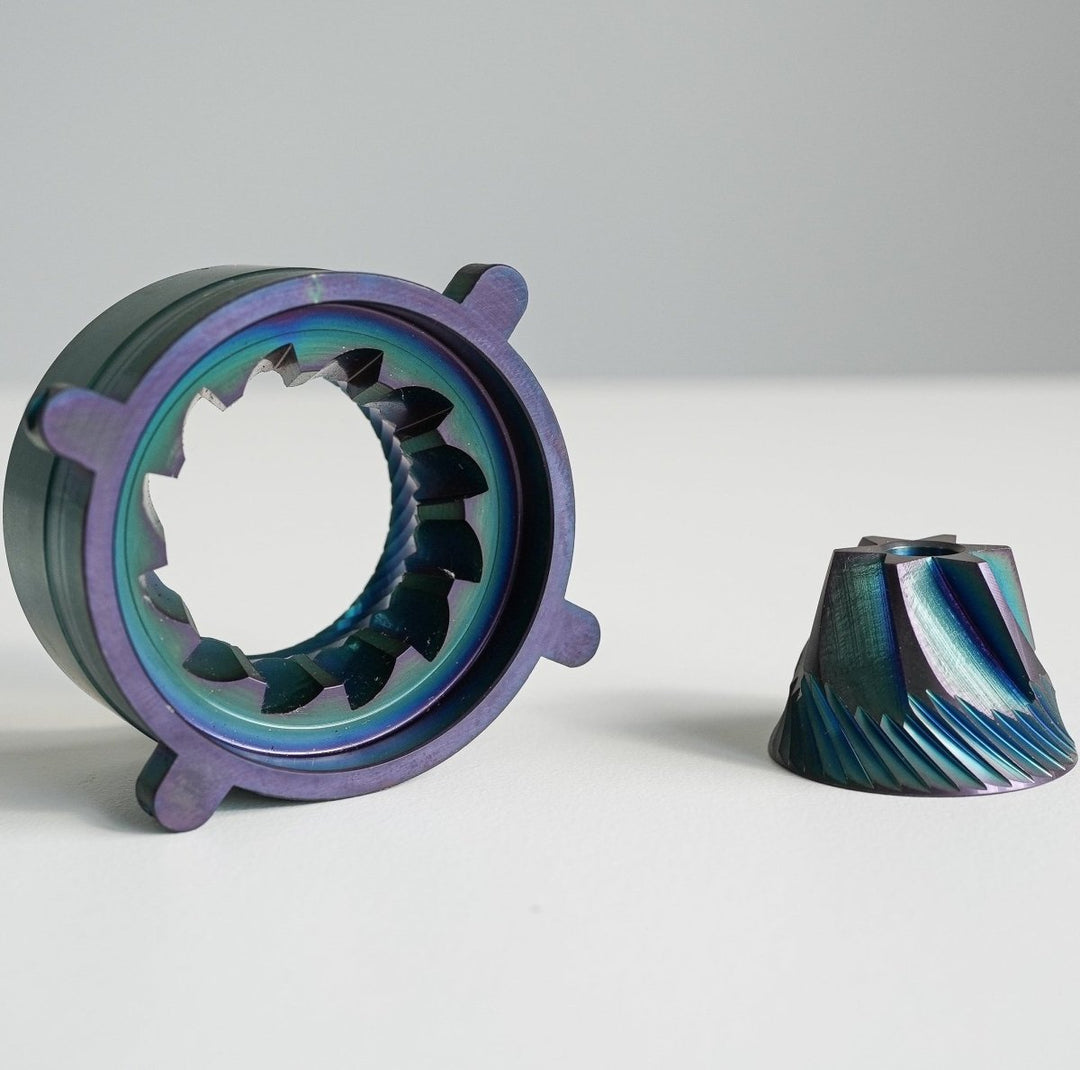

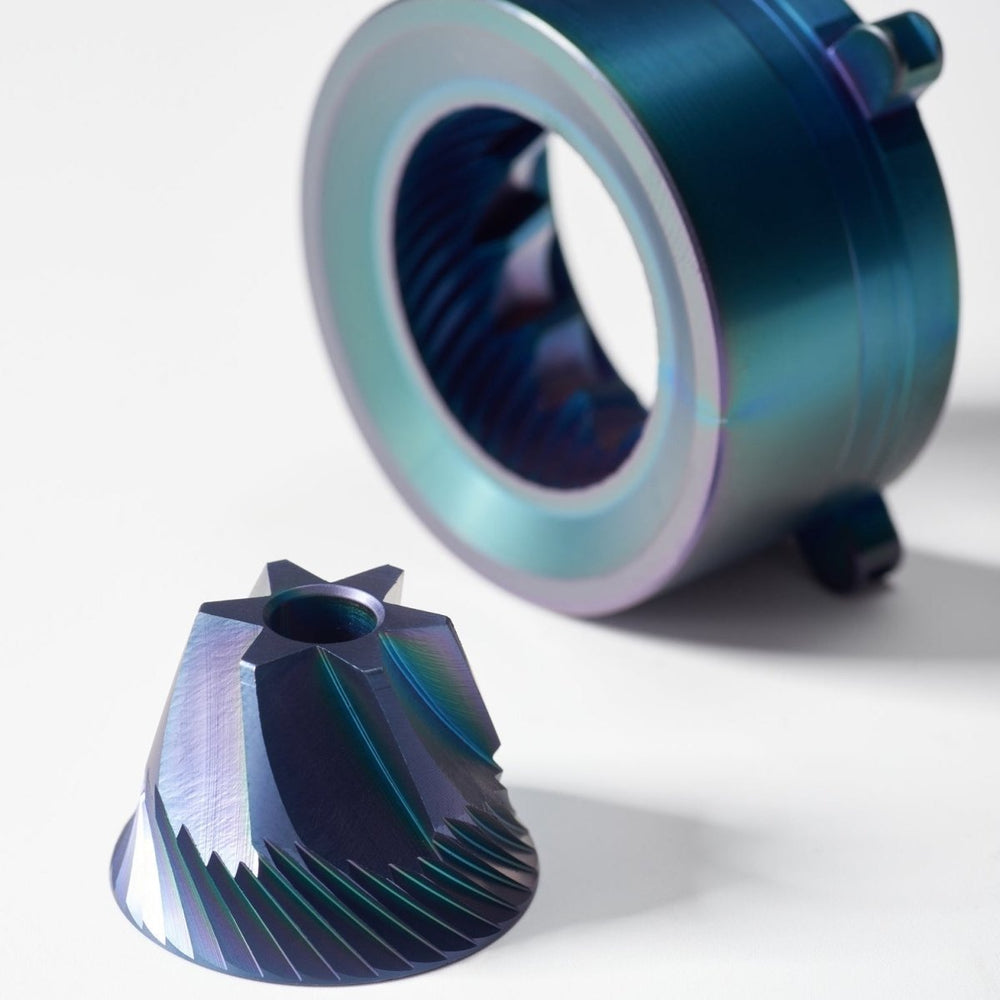

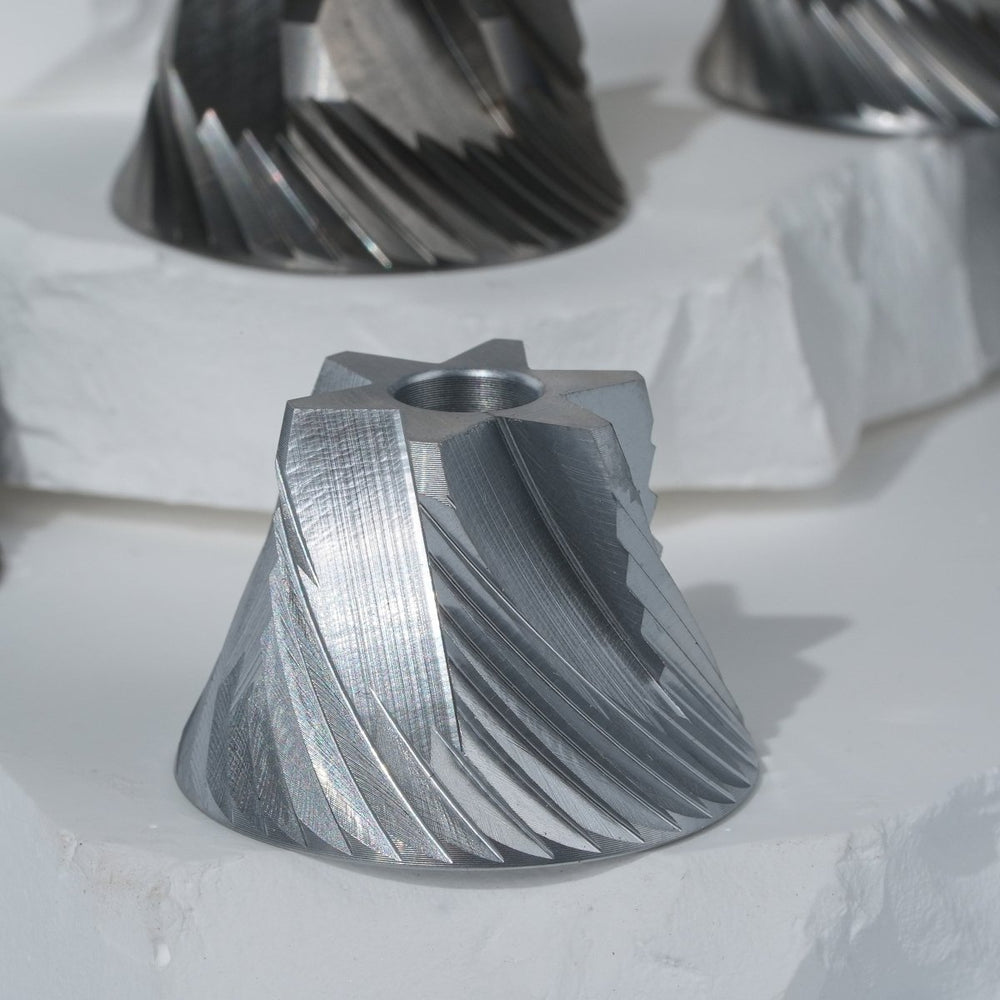

Most coffee grinder burrs are made of steel for durability, and manufacturers select materials based on the intended application, ensuring optimal performance across different materials, while others use aluminum alloys or specialty coatings like titanium for wear resistance.

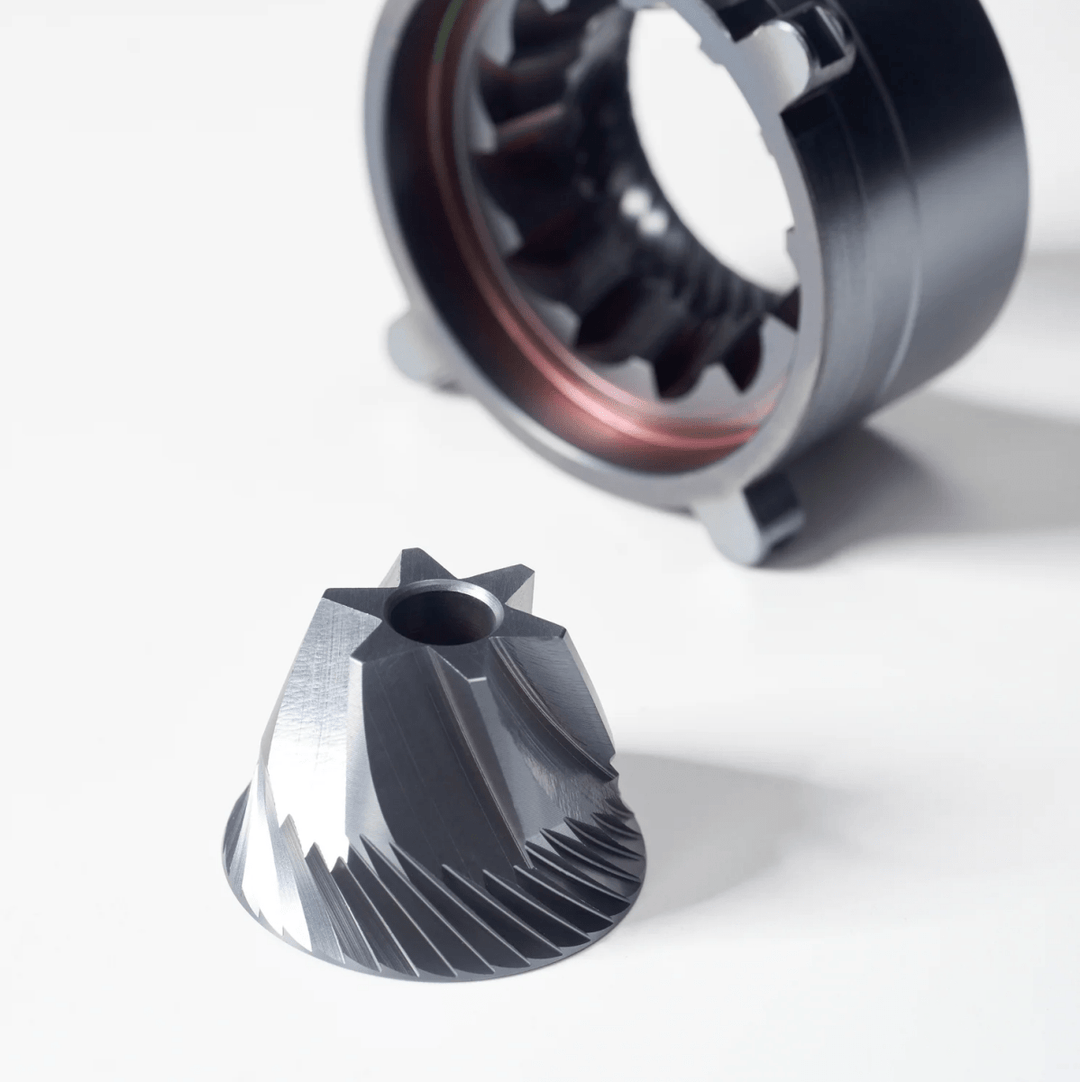

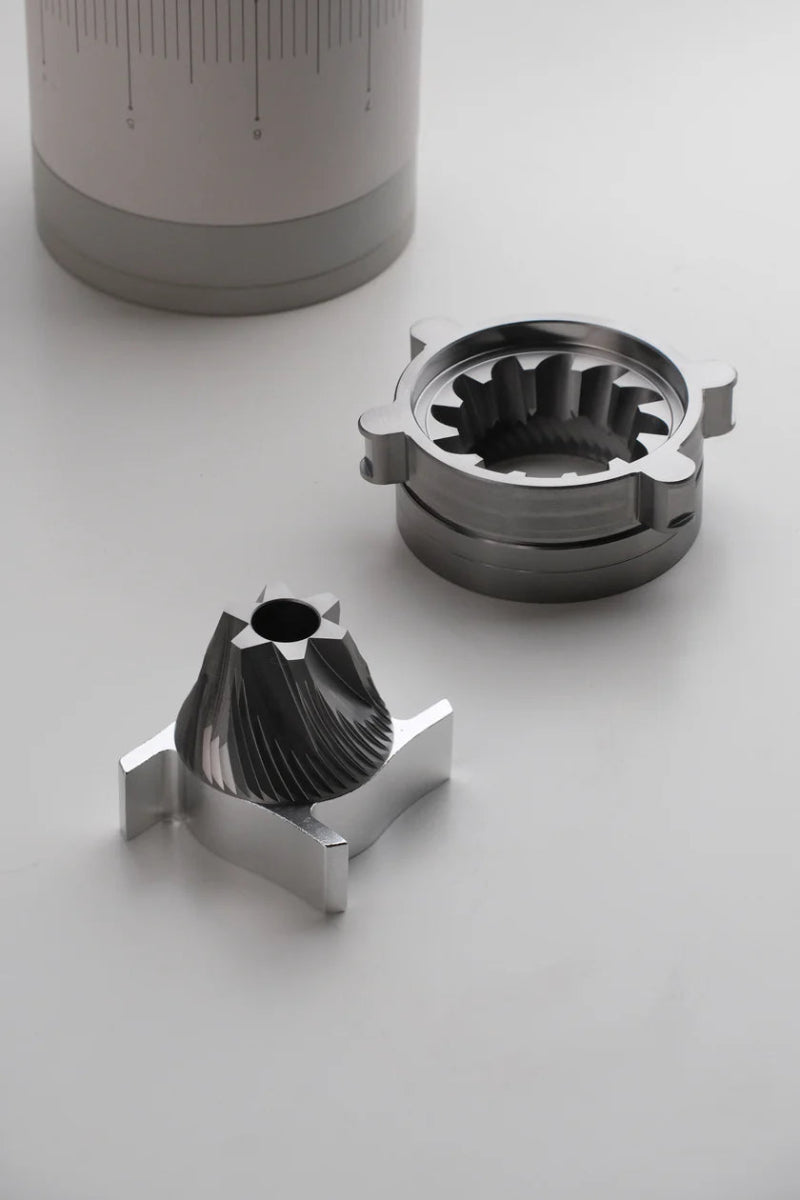

The Importance of the Burr Head Shape

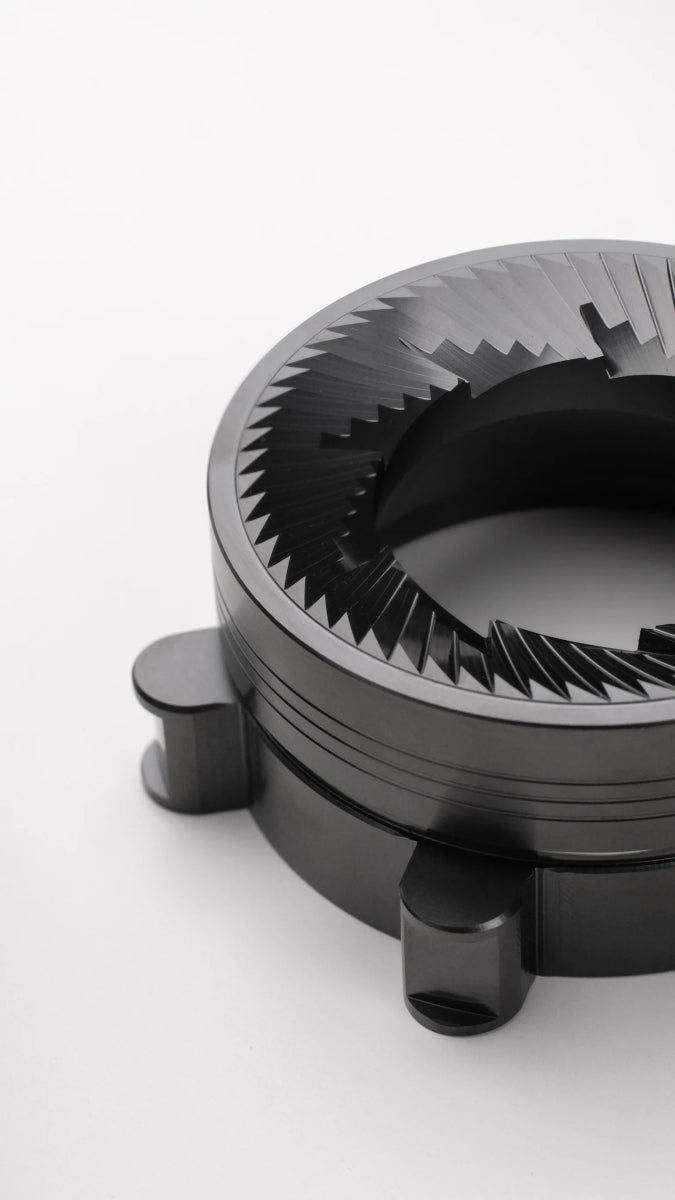

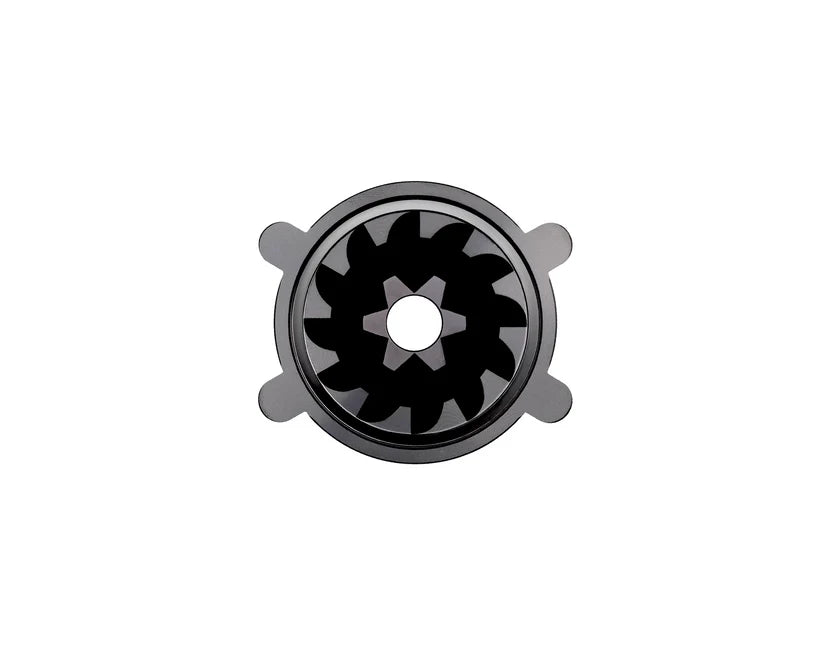

The head design affects how the beans are ground. Flat burrs often produce a more uniform grind, while conical burrs can offer a broader range of grind sizes.

Burrs in Coffee vs. Construction Tools

While coffee burrs focus on precise, low-heat grinding, construction burrs are used for deburring, cutting, and shaping metal or plastics. Both rely on quality engineering.

High-quality burrs work great for both coffee grinding and industrial applications, delivering reliable results in each use case.

Deburring – Removing Edges with Precision

In construction, deburring removes sharp edges from metal parts, a process similar in precision requirement to achieving a smooth coffee grind.

Hole Size and Burr Matching

Matching the burr size to your grinder’s hole and shank dimensions is essential for compatibility and safety.

Process – From Bean to Brew

In coffee, the process starts with coffee beans entering the burr set, where they’re ground to the desired consistency for your chosen brew method.

Grinding Techniques for Every Brew

Espresso: Fine Precision

Achieving the perfect espresso shot starts with a fine, uniform grind, and that’s where a high-quality carbide burr set truly shines. Espresso demands precision, so investing in a carbide burr or a complete carbide burr set ensures your grounds are consistent every time. Many coffee professionals in South Carolina rely on carbide burrs in their grinders for this very reason. If you’re looking for a good deal, check reviews and compare prices to find a set that balances quality and value. When using a die grinder or even a drill bit with a carbide burr attachment, it’s important to decrease the quantity of beans you grind at once—this helps prevent over-extraction and reduces unnecessary wear on your burrs. Apply steady, gentle pressure during grinding to maintain the sharpness of your burrs and extend their lifespan. Whether you’re upgrading your home setup or outfitting a café, choosing the right bit and technique can make all the difference in your espresso’s flavor and crema.

Drip Coffee: Balanced Extraction

For drip coffee, the goal is a balanced extraction that brings out the best in your beans. Using a carbide burr set with a medium-coarse grind size is ideal for this brew method. Look for burrs with a 1/4” shank, which are well-suited for most drip coffee grinders. The construction industry trusts carbide burrs for their ability to deburr metal edges with precision, and that same level of quality translates perfectly to coffee grinding. When selecting a carbide burr set, pay attention to the manufacturer’s reputation and read customer reviews to ensure you’re getting a product that delivers consistent results. Note that grind size may need to be adjusted based on your specific coffee maker and bean type, so having a reliable set of burrs gives you the flexibility to fine-tune your process for optimal flavor.

French Press: Coarse and Consistent

French press brewing calls for a coarse, even grind to produce a rich, full-bodied cup. A carbide burr set designed for coarser grinds is essential for achieving this consistency. In Mexico, many coffee shops trust carbide burrs for their durability and ability to handle the pressure of grinding larger coffee particles. Opt for a burr set with a 1/2” shank for French press grinding, as it provides the stability needed for this technique. Using the right technique—steady, even pressure and a slow, controlled grind—helps prevent over-extraction and ensures your grounds are uniform. Quality carbide burrs not only withstand the demands of frequent use but also deliver the consistent results that French press enthusiasts crave.

Burrs as a Great Product Investment

A high-quality burr is a great product because it directly affects flavor. Replacing a dull burr can instantly improve your coffee.

Performance Over Time

Burr performance can decline with heavy use. Keeping an eye on wear helps maintain cup quality.

Durability – Built to Last

The durability of carbide or coated burrs means you can grind daily without rapid degradation.

Legal Considerations in Manufacturing

Some burr designs are legal to produce in certain regions but may require patent checks—something manufacturers and lawyers deal with, not the average coffee drinker.

Additionally, some manufacturers implement strict processing and quality control procedures to ensure compliance with legal and industry standards.

Edge Precision

Sharp edges on a burr are essential for cutting evenly without crushing beans.

Quantity and Stock

Quantity availability can affect pricing. At Bean Bros, we keep burrs in stock so you can replace them when needed.

Wear and Replacement

As burrs wear, performance declines. If replacement is delayed, issues like inconsistent grind or even equipment damage have happened to users. Replacing them every two years for heavy users is a good idea.

Performance Under Pressure

Burrs must withstand significant pressure during grinding without deformation.

Shape and Grind Profile

The shape of the burr impacts how the coffee is ground and the flavor in the cup.

Ground Coffee Quality

A good burr set will produce even ground particles, enhancing extraction.

Plastics in Burr Construction

Some burr carriers or housings are made of plastics for weight reduction.

Business and Manufacturing Reputation

Manufacturers with a strong reputation in burr design, such as Varia or Kinu, are trusted by espresso enthusiasts.

Top brands are often competitively priced, offering both quality and value.

Construction Standards

High-end burrs are manufactured to strict construction standards for consistency.

Price vs. Value

While premium burrs have a higher price, they often save money over time due to better durability.

Job Suitability

Choosing the right burr for the job—espresso, filter, or cold brew—is crucial.

Putting the correct burr into your grinder ensures optimal results for each brewing method.

Kit Completeness

Some brands sell burrs as part of a kit, including tools for installation.

Mention of Global Reach

From Scotland to Mexico, burrs are used in both coffee and industry.

Promotions and Deals

Watch for promotions in June, July, or September to get a good deal.

Government Standards

Some government bodies regulate manufacturing quality for safety.

Customer Reviews

A review from a satisfied customer can guide your purchase—look for mentions of quality and performance.

For example, one customer wrote, "Reviewed in the United States on February 12, 2023: Excellent quality and fast shipping." Another review from March 2022 states, "In March, I purchased this product and was impressed by its performance." A recent review from November 2023 highlights, "Reviewed in November, the durability and reliability exceeded my expectations."

Proved in Practice

Burrs that have proved their reliability over two years of use are worth investing in.

Monthly Trends

Some coffee pros replace burrs in January or April as part of a maintenance routine.

Form and Function

The form of a burr is as important as the material.

Protect Your Investment

Regular cleaning helps protect burr edges from oil buildup.

Bit and Drill Bit Comparisons

While burrs and drill bits are different tools, both require precision material removal.

From South Carolina to Scotland

Whether in South Carolina workshops or Scotland cafés, burrs are central to quality work.

Our Bean Bros Burr Selection

At Bean Bros, we offer premium burr upgrades for coffee grinders:

FAQ – Burr

Q: How often should I replace my coffee grinder burrs?

A: For home use, every 2–3 years; for cafés, annually.

Q: Are carbide burrs better than steel burrs for coffee?

A: Steel is standard for coffee, but carbide coatings can increase lifespan.

Q: Can burrs affect coffee flavour?

A: Yes, sharp, well-maintained burrs produce more even grounds and better extraction.

Q: What’s the difference between a burr and a blade grinder?

A: Burrs grind consistently, while blades chop unevenly.

Q: Do all burrs fit all grinders?

A: No, always check size and compatibility before purchasing.